This Craft and Study of Tailored Wrapper Systems Fabrication

Within the current dynamic industrial environment, the need for innovative plus creative packaging solutions has reached unprecedented levels. Businesses from multiple sectors are gradually looking to bespoke packaging equipment machinery manufacturers to satisfy their unique demands. These producers hold a key role in creating tailored mechanisms that boost productivity, minimize excess, and improve the overall packaging method.

Custom packing is more than concerned with function; it merges design and science to deliver results that are simultaneously effective and visually appealing. By harnessing advanced technology and complying with industry standards, these manufacturers engineer equipment that aid organizations enhance their workflows. This write-up explores the complex process of custom packaging machinery production, emphasizing the knowledge and creativity involved in producing machinery that satisfies the different requirements of diverse industries.

Grasping Custom Product Packaging Equipment

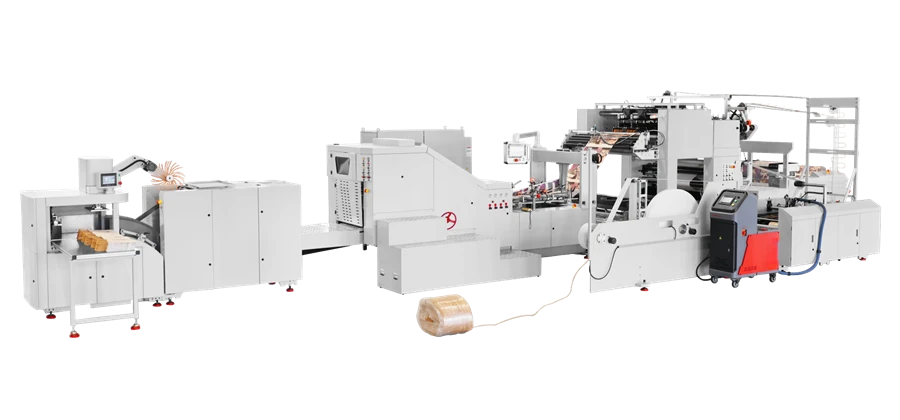

Tailored packaging solutions machinery holds a a vital role in various sectors by making sure goods are packaged effectively and securely. This machinery is customized to satisfy the unique requirements of various businesses, handling varied product shapes, dimensions, and enclosing materials. By integrating advanced technology and creative designs, custom packaged goods solutions minimize manual labor, lessen wastage, and enhance productivity.

One key component of bespoke product packaging machinery is its ability to streamline processes. Mechanization significantly hastens the packaging workflow, enabling companies to match growing demand. This not only results in cost savings but also improves the reliability and caliber of the packaging process. Custom machinery can feature elements like customizable settings for different package types and computerized quality checks, confirming that all item fulfills rigorous standards before it arrives at consumers.

Furthermore, working together with a bespoke product packaging equipment supplier permits businesses to customize each detail of the packaging process. From the first design plans to the ultimate production, manufacturers team up with clients to grasp their specific demands. This collaboration not only encourages new ideas but also supports companies stay in the game in a quickly changing environment by leveraging the latest product packaging technologies and techniques.

Important Innovations for Production

Regarding the field of custom packaging machinery manufacturing, advanced technologies play a vital role in improving productivity and precision. Automated technology is one of the foundational elements driving progress in this industry. By integrating robotic systems and automated workflows, manufacturers can optimize production processes, reduce human error, and increase output. Automation not just speeds up operations but also enables greater customization, permitting manufacturers to tailor machines to the specific needs of each client.

A key technology is the use of computer-aided design (CAD) and CAM (CAM) systems. CAD software allows engineers to create comprehensive 3D models of packaging machinery, facilitating design and modification before any physical components are produced. CAM systems then transform these designs into implementable instructions for manufacturing equipment, ensuring that every part is produced with superior accuracy. This synergy between design and production substantially reduces lead times and enhances overall product quality.

In conclusion, the integration of Industry 4.0 principles is changing custom packaging machinery manufacturing . This involves the implementation of intelligent technologies such as the Internet of Things (IoT) and data analytics. Machines equipped with IoT capabilities can acquire and send real-time data, which can be examined for performance optimization and predictive maintenance. By leveraging this data, manufacturers can improve operational efficiency, reduce downtime, and deliver more reliable packaging solutions to their clients.

Benefits of Bespoke Container Strategies

Custom wrapping tools provides significant gains for companies looking to enhance their production efficiency. By customizing tools to specific manufacturing requirements, businesses can optimize their workflows and reduce delays. This optimization leads to improved productivity and faster turnaround times, which are crucial in competitive markets. Bespoke approaches ensure that systems fit seamlessly into pre-existing frameworks, lessening disruption and maximizing output.

Another significant gain of tailored packaging options is the potential to adequately meet client demands. Custom machinery can be engineered to accommodate specific wrapping specifications, such as diverse shapes, sizes, and materials. This versatility allows producers to react swiftly to changing market trends and client preferences, ultimately leading to higher satisfaction rates. Companies can access specialized markets and offer distinctive products that distinguish themselves on the shelf.

Finally, bespoke wrapping options enhance sustainability efforts. Custom machinery can be created to use supplies more productively, minimizing waste and energy consumption throughout the manufacturing process. This method helps businesses align with sustainability goals and regulations, which are increasingly important to consumers and stakeholders alike. By allocating https://www.saludcapital.gov.co/sitios/VigilanciaSaludPublica/Lists/Contactenos/DispForm.aspx?ID=2972663 in bespoke wrapping equipment, manufacturers not only boost their profitability but also contribute to a more eco-friendly future.