The Overlooked Pioneers of Packaged Goods: Attention on Tailored Equipment

In the dynamic world of product delivery and retail, container design often takes a back seat to more eye-catching elements like advertising and branding. Yet, it is the often unnoticed champions of packaging, particularly custom machinery manufacturers, that play a pivotal role in making sure products arrive at consumers securely, efficiently, and in an effective manner. These specialized manufacturers develop and create tailored solutions that address the specific needs of various industries, shaping how goods are presented and showcased to the market.

Tailored packaging machinery is not just about performance; it is about innovation and creativity in a field that is constantly progressing. Whether it’s adapting to new materials, customizing machinery for specific product sizes, or integrating advanced technology for improved automation, these manufacturers are at the leading edge of transforming packaging processes. Their input, while often overlooked, are crucial in making sure that products not only look appealing on the shelf but are also wrapped with accuracy, lowering waste and boosting overall effectiveness in delivery.

The Growth of Tailored Packaging Solutions

In the past few years, the field of packaging has undergone significant transformation, primarily influenced by the growing demand for customized options across different industries. Tailored packaging equipment has emerged as a critical element, enabling manufacturers to fulfill distinct requirements while enhancing performance and reducing inefficiency. This rise can be attributed to the growing emphasis on green practices, as businesses seek new ways to reduce their carbon footprint while delivering products that resonate with consumers.

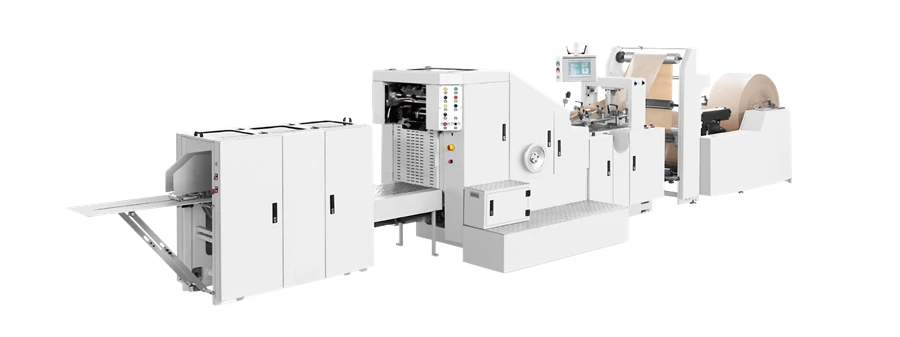

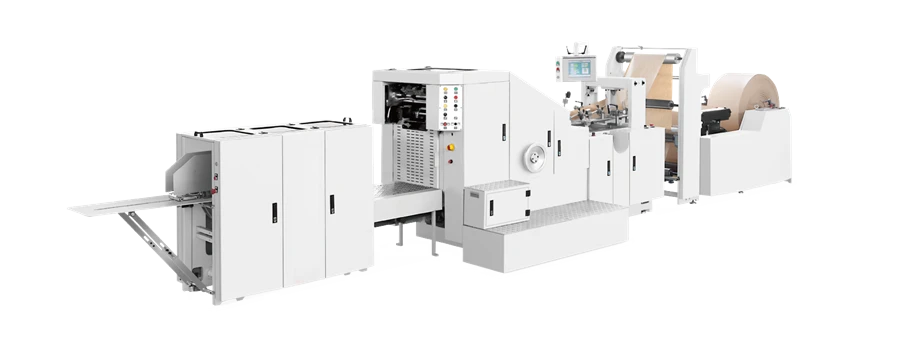

As manufacturers acknowledge the significance of tailoring, the role of custom packaging machinery has become more pronounced. Off-the-shelf products often fail in addressing specific challenges, such as different product sizes and shapes, unique materials, and different production speeds. https://www.bitsdujour.com/profiles/HyUrCg allows manufacturers to streamline their operations, ensuring that they can respond to the evolving market demands without compromising on quality or speed.

Additionally, technological advancements have played a vital role in the rise of custom packaging machinery. https://wikimapia.org/external_link?url=https://www.jiandajx.com/category/paper-extrusion-laminating-machinee.html , artificial intelligence, and data analytics have introduced new opportunities for improvement and precision in packaging processes. These technologies empower manufacturers to design machinery that not just meets their immediate needs but also allows for flexibility and scalability as their businesses develop. As a result, custom packaging machinery is becoming a key ally in the search for operational excellence and competitive advantage.

Key Innovations in Packaging Technology

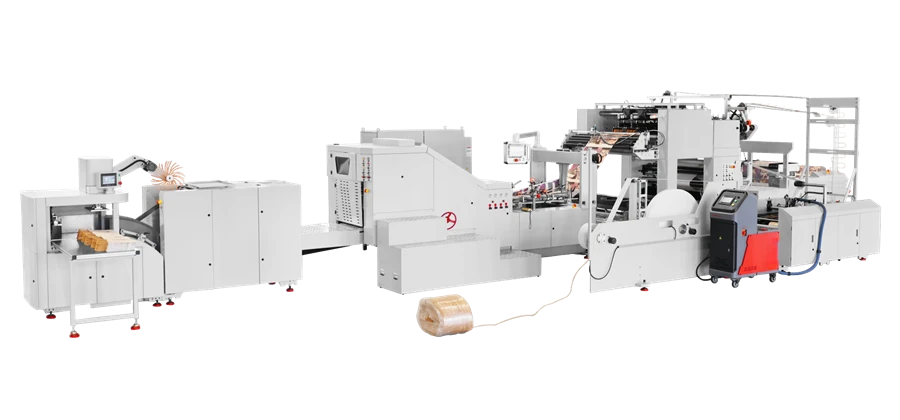

The landscape of custom packaging machinery has been changed by new innovations that address a wide range of industries. Improvements in automation technology have streamlined production processes, allowing manufacturers to create packaging at an unmatched speed. Robotics have become more common, enabling machines to handle challenging tasks such as arranging, packing, and stacking with improved precision and reduced labor costs. This transition not only boosts efficiency but also ensures consistency and quality in packaging solutions.

A further development is the incorporation of smart technology into packaging machinery. Internet of Things (IoT) and sensors provide immediate data, allowing manufacturers to monitor and adjust operations for best performance. This connectivity allows for predictive maintenance, reducing downtime and improving the overall efficiency of the packaging process. Furthermore, smart machinery can flex to various production needs, making it more convenient for companies to switch between product lines without major retooling.

Environmental responsibility has also grown as a key focus in packaging machinery innovations. Custom packaging machinery manufacturers are more and more designing systems that utilize green materials and low-energy processes. Technologies that facilitate the use of biodegradable and recyclable materials are becoming commonplace, coinciding with consumer demand for more sustainable practices. https://skitterphoto.com/photographers/982248/wise-thybo are now investing in machinery that not only meets their operational needs but also reinforces their commitment to eco-consciousness, paving the way for a more sustainable packaging future.

Benefits of Tailored Solutions in the Sector

Custom packaging machinery offers significant advantages for businesses looking to enhance their operational processes. By customizing machinery to particular requirements, companies can guarantee that they are using equipment that exactly fits their operational needs. This customization leads to enhanced efficiency, reducing downtime and minimizing waste. Off-the-shelf machinery may not accommodate specific product dimensions or packaging types, but tailored solutions provide the adaptability needed to adapt to various products and packaging styles.

Another key benefit of custom packaging solutions is increased scalability. As companies develop and their product lines widen, having machinery that can change with them is essential. Tailored equipment can be designed with scalability in mind, enabling manufacturers to easily integrate new features or alter the existing ones without a complete revamp. This versatility not only conserves time but also significantly reduces costs involved in purchasing new equipment and training staff.

Finally, investing in tailored packaging machinery can lead to improved overall product quality. Well-designed machinery operates consistently and accurately, ensuring that products are packaged efficiently and attractively. This consistency helps to maintain brand reputation and customer satisfaction. jiandajx include advanced technology to monitor and refine processes in real time, further enhancing the quality of the packaging and the protection of the products inside.