Dual Layer Stretch Plastic Machines: A Breakthrough for Factories

In the rapid world of production and wrapping, productivity and excellence are critical. As companies strive to reduce expenses while maintaining top quality, advanced machinery plays a crucial role in realizing these goals. One such development that is changing the industry is the double layer stretch film making machine. http://iki-iki.sakura.ne.jp/members/miyano/mtgwiki/index.php?decadeglass9 improves the manufacturing process but also raises the quality of the final product, making it a breakthrough for manufacturers.

The double layer stretch film making machine offers a distinct solution for producing stretch films that are stronger and versatile than ever before. By incorporating https://www.nunesmagician.com/users/haybruun77xeu of substrate, this machine provides enhanced strength and flexibility, meeting the rising demands of modern packaging applications. Manufacturers are finding that spending in this machine can lead to significant improvements in their operational effectiveness, material efficiency, and overall product performance. As the market continues to evolve, the double layer stretch film making machine stands out as a key tool for those looking to keep ahead of the market.

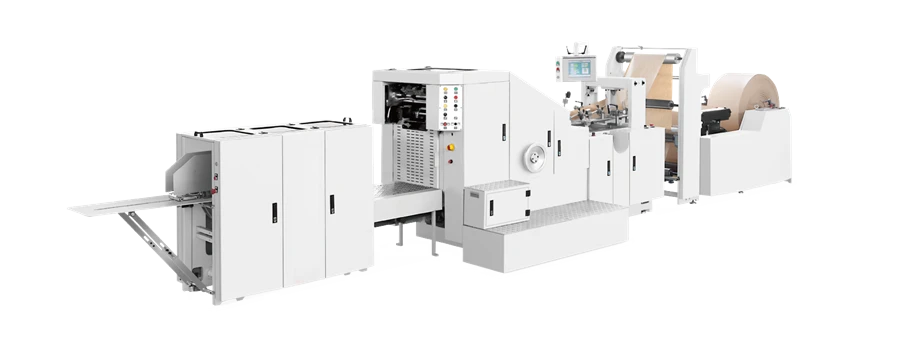

Overview of Dual layer Stretch film Systems

Two-layer stretch wrapping systems are revolutionizing the packaging industry by offering improved effectiveness and versatility. These systems are designed to create stretch wraps that feature dual distinct strata, allowing manufacturers to develop films that integrate different features. This advancement enables the manufacturing of wraps that can achieve superior durability, abrasion resistance, and clarity compared to single-layer films.

One of the main benefits of dual layer stretch film machines is their ability to optimize material usage. By producing wraps with diverse formulations, manufacturers can adapt their packaging solutions to the particular needs of their products. This produces lowered expenditure on materials and waste, while still maintaining elevated performance in load integrity and safeguarding during shipping and warehousing.

Furthermore, the efficiency of operation of dual layer stretch film machines is crucial to increasing production output. With the capacity to handle dual layers of film, manufacturers can achieve faster production times and meet the rising need for high-quality packaging solutions. As a result, these systems are becoming a preferred choice for organizations looking to improve their production processes and upgrade their packaging solutions.

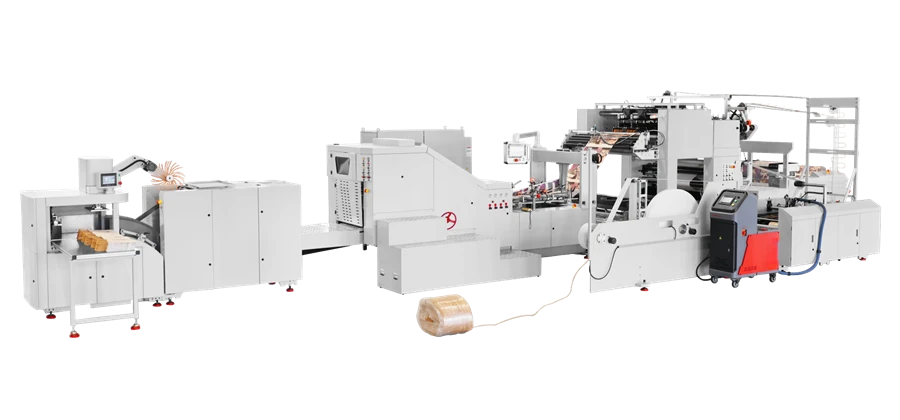

Advantages for Manufacturers

The Double Layer Stretch Film Making Machine offers increased efficiency in the production process. By making two layers at the same time, manufacturers can significantly reduce production time and increase output. This feature facilitates a more efficient workflow, lessening the need for multiple machines and reducing downtime during the manufacturing cycle. As a result, companies can meet rising demands while maintaining quality.

Another advantage is the improved strength and durability of the stretch film produced. The dual-layer technology provides better control over the properties of each layer, resulting in stretch films that are both durable and adaptable. This superior performance ensures optimal protection for products during transportation and storage, which is vital in today’s dynamic market. Clients benefit from higher-quality packaging solutions that can withstand various conditions, leading to increased customer satisfaction.

Cost-effectiveness is also a key benefit for manufacturers utilizing this technology. The Dual Layer Stretch Film Making Machine lowers the amount of raw materials needed by optimizing film performance, ultimately leading to reduced production costs. Additionally, jiandajx to produce high-quality film can reduce loss and improve overall profitability. As manufacturers seek to tighten their budgets, these machines present an opportunity to achieve superior financial outcomes while maintaining high standards.

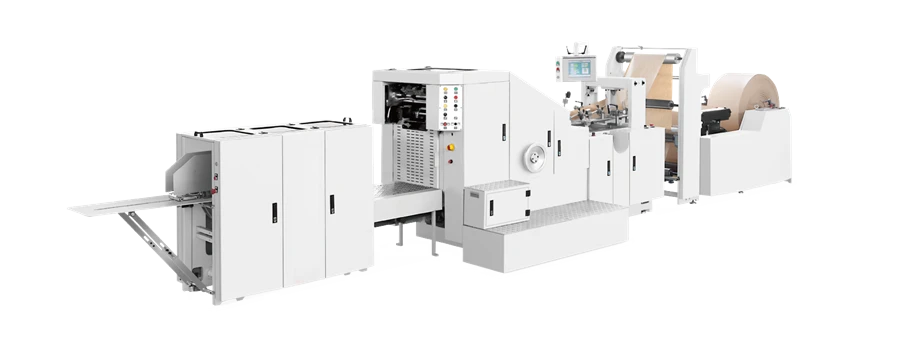

Future Innovations in Stretch Packaging Film Science

As companies persist to look for ways to improve productivity and reduce expenses, the development of double layer stretch packaging film production machines is on the horizon. These machines are becoming increasingly advanced, integrating cutting-edge automated systems and artificial intelligence to optimize production processes. With instant monitoring systems, manufacturers can currently modify parameters on-the-fly, yielding higher film quality and lessened material wastage. This tech breakthrough will undoubtedly set novel benchmarks for velocity and precision in the stretch packaging film industry.

Eco-friendliness is another significant trend shaping the coming of flexible film technology. As environmental concerns increase, manufacturers are proactively exploring biodegradable and sustainable materials for stretch films. Two-layer stretch packaging film production machines are being adapted to work with these new materials without sacrificing the strength and flexibility of the film. This shift not only addresses customer demands for Eco-friendly products but also positions producers as responsible pioneers in the field, addressing the pressing problem of plastic pollution.

Additionally, the increasing trend of customization in packaging shapes the design of stretch film machines. Producers are more and more investing in machines that allow for flexible production runs, enabling them to create customized films that cater to specific needs. Innovations such as multi-layer structures and adjustable thickness options are expected to become more prevalent, allowing companies to differentiate their products in challenging markets. This flexibility will boost the value proposition of two-layer flexible packaging film making machines, making them vital tools for forward-thinking producers.